When it comes to measuring and improving the environmental impact of a product, one size does not fit all. Selecting the right type of Life Cycle Assessment (LCA) is crucial. The goal and scope of your project will ultimately determine which LCA approach best supports your sustainability journey.

We help organizations navigate these options to ensure their efforts are both scientifically robust and strategically impactful. Below, we break down the main types of LCAs and how to choose the one that fits your organizations needs.

Life Cycle Assessment: Measuring Environmental Impact

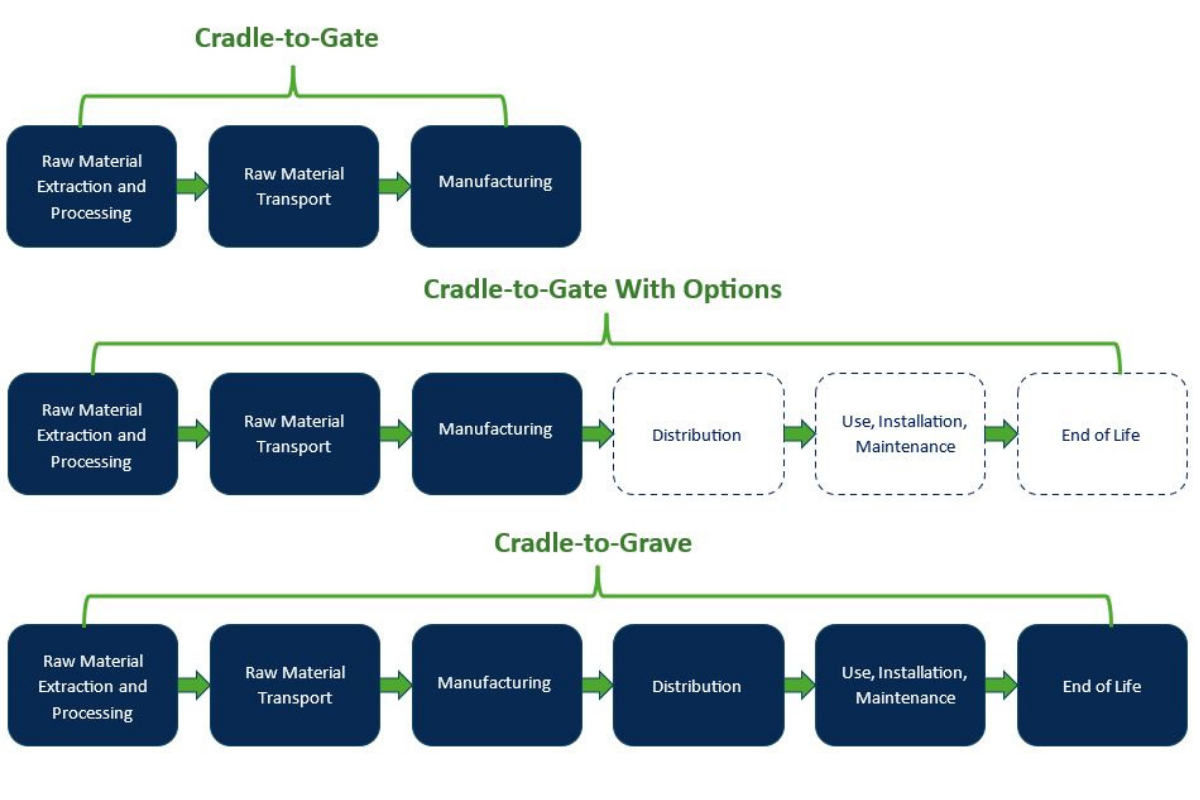

A standard LCA is designed to calculate the environmental impacts of a product or process across its life cycle. This assessment typically follows one of three system boundaries:

Cradle-to-gate: From raw extraction to the factory gate

Cradle-to-gate with options: Includes additional stages like distribution or use, depending on project goals

Cradle-to-grave: Covers the entire life cycle, from raw material extraction to end-of-life disposal

These studies are developed in accordance with ISO 14040 and ISO 14044 standards and require a third-party critical review if shared externally. This type of LCA provides a comprehensive environmental snapshot, empowering companies to understand and communicate their product footprints with confidence.

Life Cycle Assessment Optimized: Driving Improvement

An optimized LCA calculates and compares environmental impacts of a new generation of a product or process against a baseline.

The system boundary should match that of the original study to ensure consistency, whether cradle-to-gate, cradle-to-gate with options or cradle-to-grave. The study is developed to ISO 14040/ISO 14044 standards and also includes an overview of methods for optimization including:

Improving Operational Efficiency

Innovating Product Design

Reducing Packaging

A third-party critical review of the optimization results is conducted to ensure the findings are credible and transparent; an essential step if results will be shared publicly.

Comparative Life Cycle Assessment

When the goal is to compare two distinct products or processes, a Comparative LCA is the gold standard. This assessment calculates environmental impacts to support marketing claims, for example, showing how a new product performs better than an incumbent option.

System boundaries must be fully inclusive and consistent, whether cradle-to-gate, cradle-to-gate with options or cradle-to-grave, to ensure an “apples-to-apples” comparison.

The study is developed to ISO 14040/ISO 14044 standards and requires primary data for both systems. A rigorous third-party review process by a three-person panel is conducted, especially if results are to be shared externally.

Defining Your System Boundary: Setting the Scope of Your LCA

The depth and the breadth of an LCA can vary considerably depending on the goal and scope of the study. The “system boundary” defines which life cycle stages are included in your analysis and is a critical factor in every LCA. For building and construction products, the system boundary is defined by the Product Category Rule (PCR). If a PCR does not exist, the system boundary must align with the standards used to develop the study

(i.e., ISO 21930 or EN 15804+A2/AC).

The image below represents the three most common system boundaries used in LCA.

Which LCA is Right for Your Organization?

Choosing the right type of LCA is not always straightforward. That’s where SSC’s expert guidance comes in. Our quick 7-question Readiness Assessment can help you determine the most suitable LCA approach based on your goals, industry, location, and priorities.

Meet the Expert

Cara Vought, LCACP

Senior Technical Consultant

Cara has over 13 years of experience in product stewardship and corporate sustainability strategy. She specializes in developing life cycle assessments (LCAs) and product carbon footprints, conducting independent LCA reviews to ISO standards, supporting industry associations and collaboratives in program development, and facilitating audits for sustainable manufacturing initiatives and LEED certifications.

She earned a Bachelor of Science in Chemical Engineering from the University of Delaware, with minors in Sustainable Energy Technology and Environmental Engineering. Cara also served as an adjunct professor at Jefferson University, where she taught architecture and design students how to think about materials sustainably. She believes that sustainability is an ever-evolving field that requires continuous learning and adaptation. With a passion for education, she works closely with SSC’s clients to help them expand their knowledge and integrate sustainability into their business practices.