As sustainability becomes a critical driver in today’s business landscape, waste minimization and zero waste to landfill are emerging as essential strategies for organizations aiming to reduce their operational costs, environmental impact, and meet carbon reduction goals. Together, these efforts help companies reduce the volume of waste generated, while ensuring that any remaining materials are diverted from landfills through reuse, recycling, composting, or energy recovery.

Why Waste Minimization Matters for Carbon Reduction

As companies work toward carbon reduction and neutrality goals, the focus often begins with Scope 1 emissions (the fuels your company burns) and Scope 2 emissions (the energy your company buys). However, Scope 3 emissions—which stem from activities across a company’s entire value chain—often account for the largest portion of total emissions. These include everything from upstream transportation and purchased good and services to downstream impacts like product use and end-of-life treatment of sold products.

The Connection Between Scope 3 Emissions for Materials and Waste

Manufacturing waste and product disposal are two categories within Scope 3 emissions that may contribute to a company’s overall emissions profile. Waste is considered a Scope 3 emission because, although companies generate it through their operations and products, the actual disposal is typically handled by external parties. This distinction means organizations are accountable for the impact of the waste they produce, even if they don’t manage its end-of-life.

Waste directly aligns with Scope 3 Category 5 (Waste Generated in Operations), as well as Scope 3 Category 1 (Purchased Goods) and Scope 3 Category 12 (End-of-Life Treatment of Sold Products). These categories represent key points in the value chain where emissions are attributed to materials a company purchases, uses, and ultimately sells to customers.

Category 5: Waste Generated in Operations

Emissions related to third-party disposal and treatment of both solid waste and/or wastewater from your company’s owned or controlled operations.

Minimize Emissions: Most waste management methods will generate greenhouse gas (GHG) emissions. The key is understanding how to minimize and manage waste in a way that results in the lowest emissions. For example, organic materials like lunchroom food waste, paper, and cardboard will break down in a landfill and produce methane — a greenhouse gas 28 times more potent than carbon dioxide.

Reduce Risk: Companies must consider regulatory and liability risks associated with how materials, especially hazardous waste, are managed. Effective diversion strategies and compliant handling can reduce Scope 3 emissions and protect against future environmental and legal exposure.

Maximize Savings: Increase profitability by focusing on waste reduction at the source—through process re-engineering, data-driven efficiency improvements, and strategic handling of complex waste streams. SSC has seen firsthand how a single facility can unlock millions in savings and transform waste into a powerful driver of profitability.

Category 1: Purchased Goods

Emissions related to the production of any products purchased or services acquired by your company in the reporting year.

Reduce Raw Material Loss: Most companies lose raw materials and packaging due to inefficiencies in production — such as damage, spills, startup/shutdown waste, or quality-related rejections. Implementing waste minimization practices in manufacturing operations can reduce the quantity of raw materials and packaging that need to be purchased thereby lowering costs, decreasing waste, and ultimately decreasing Scope 3 emissions associated with purchased goods.

Category 12: End-of-Life Treatment of Sold Products

Emissions related to the end-of-life treatment/waste management of sold products by consumers. This category requires assumptions to be made about the type of end-of-life treatment by consumers (e.g. landfill, incineration, recycling, etc.)

Compliance with Extended Producer Responsibility: Many companies produce products that create some waste in the use-phase whether it is a consumer product — for example:

shampoo with the bottle

toothpaste in a tube and a box

packaged/processed food and beverages

pharmaceutical packaging

The end-of-life management of those materials is part of Category 12 and there are currently multiple states and countries that have Extended Producer Responsibility regulations on the management of these materials. Compliance with this regulation becomes a potential direct cost to the company that produces the products and needs to be considered as part of an overall sustainability and risk management program.

What is Sustainable Materials Management?

Sustainable Materials Management examines all materials utilized within a company through a life cycle lens — from utilization, management, and end-of-life. The goal is to identify opportunities to minimize waste and implement best practices for managing materials in ways that reduce both environmental impact and costs.

SSC leverages Life Cycle Assessment (LCA) to understand the lifecycle of materials, products, and packaging including how waste and products are managed at end-of-life. When paired with our Sustainable Product Innovation process, this approach enables companies to design waste out of their operations, improve material efficiency, and proactively address regulatory risks such as Extended Producer Responsibility (EPR) requirements in various states and countries.

SSC’s Operation Zero Waste proven process applies these principles in a structured, actionable way enabling companies to minimize waste, lower emissions, and improve operational performance.

What is Zero Waste to Landfill?

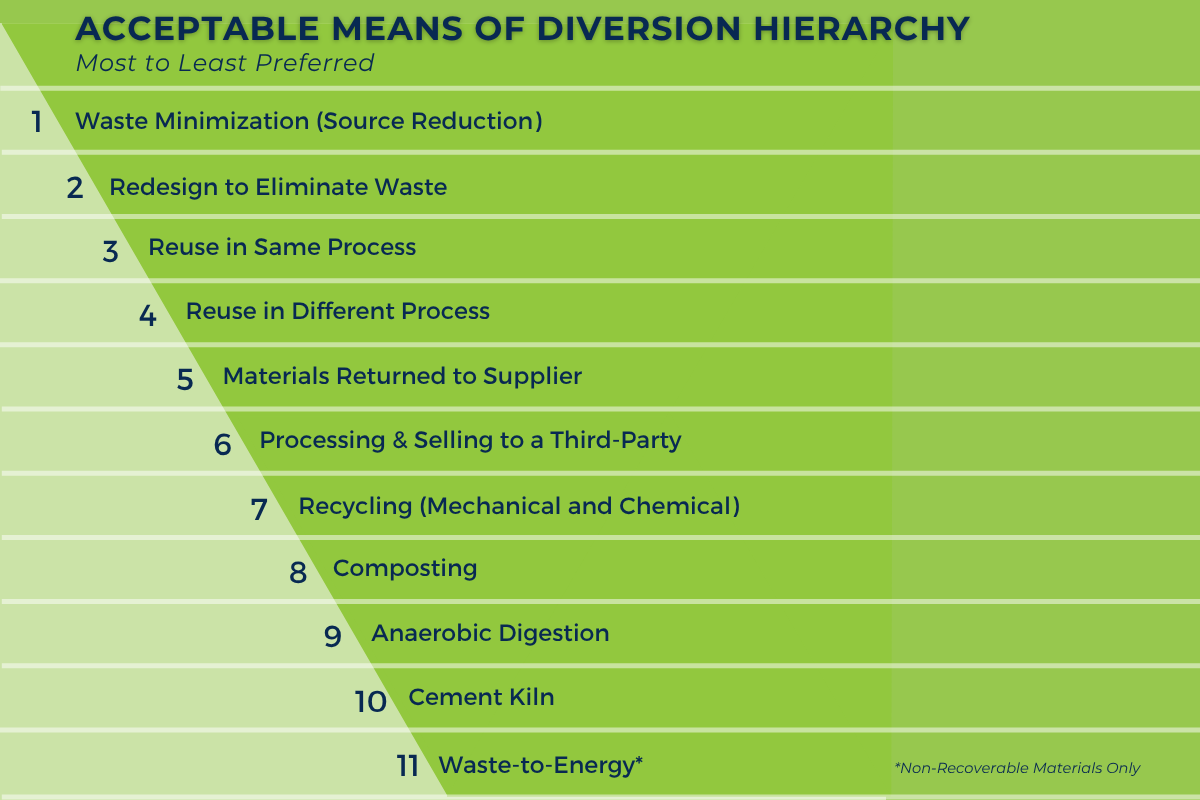

Zero waste to landfill refers to the diversion of 100% of a facility’s waste away from landfills. This approach involves sending waste streams to material management organizations (MMOs) that handle recycling, composting, or other approved waste diversion methods.

While many organizations engage in some form of recycling, a more comprehensive approach to waste minimization and resource recovery can lead to greater environmental and operational benefits. This includes evaluating all waste streams and exploring opportunities to reduce, reuse, and divert materials more effectively.

Why Zero Waste to Landfill Matters

Organizations that prioritize waste minimization gain a competitive edge by strengthening their sustainability performance and improving operational resilience. A zero-waste approach:

Reduces operational costs

Minimizes environmental and regulatory risk

Enhances brand credibility and trust

Meets increasing expectations from customers, investors, and partners

Waste diversion is also a key lever for lowering Scope 3 emissions, which include the indirect impacts of a company’s supply chain—such as how waste is managed after it leaves the facility. Diverting waste from landfills helps avoid methane emissions and supports both climate goals and long-term business value.

The SSC Approach: Operation Zero Waste

Operation Zero Waste, our proven 8-step framework (referenced above), is designed to help organizations achieve zero waste to landfill targets. The process starts with a detailed assessment of all facility-generated waste, including an on-site evaluation to measure, characterize, and quantify each waste stream.

From there, SSC partners with facility teams to build a customized waste diversion roadmap—identifying opportunities for source reduction, material reuse, and innovative strategies tailored to each operation’s unique challenges.

In one example, SSC collaborated with a Fortune 500 pharmaceutical company to uncover over 400,000 pounds of waste diversion potential, translating into approximately

$2 million in projected annual savings. This outcome demonstrates that strategic waste reduction not only advances sustainability goals but can also deliver measurable financial value.

“Waste is often an overlooked contributor to Scope 3 emissions, yet it presents a major opportunity to cut costs and mitigate risk. A structured waste minimization strategy—paired with zero waste to landfill goals—can reduce material purchasing, lower disposal expenses, and decrease liability from downstream methane emissions, all while supporting science-based carbon reduction targets.”

Tad Radzinski, PE, SEP, LEED AP, SFP | SSC President

Your Roadmap to Zero Waste Starts Here

Achieving zero waste to landfill is a powerful step toward long-term sustainability—and a practical way to reduce emissions, manage risk, and optimize operations. Whether you’re a manufacturer, corporate office, or event organizer, SSC’s Operation Zero Waste provides the structure and expertise to help you meet your goals.

Ready to take the next step? Take our quick readiness assessment to see if your company is prepared to launch a Zero Waste to Landfill initiative. It's a simple way to evaluate your current practices and identify where to begin.

Meet the Expert

Tad Radzinski,

PE, SEP, LEED AP, SFP

Co-Founder & President

Tad Radzinski is a recognized sustainability expert and former EPA Waste Minimization National Expert with over 35 years of experience advising Fortune 500 companies. He is Co-founder and President of Sustainable Solutions Corporation, providing decarbonization consulting and training across industries, and Co-founder of GreenCircle Certified, which verifies sustainability claims for top brands like P&G, 3M, and Amazon.

Tad co-hosts the Tad Talks Sustainability podcast, simplifying complex topics and featuring major companies. He also helped develop Villanova University’s MS in Sustainable Engineering and taught there for 18 years, covering Life Cycle Assessment and Sustainable Buildings and Operations.

Related Insights

DOWNLOAD: How to Achieve Zero Waste to Landfill

LISTEN: Incorporating the Circular Economy Mindset into Product Packaging with As You Sow

READ: Maximizing Profit through Waste Reduction

LISTEN: A Roadmap to Reducing Waste with Subaru